This says it all. Author unknown!

73, Lee ZL2AL

Tube VS Pipe In the manufacturing industry one often hear terms such as pipes or tubing. To those working in this industry it is often not clear what the difference is between a pipe and a tube. After all they’re both just hollow cylinders, so many people think that the word has the exact same meaning. That is however wrong. There are a couple of key differences between tubes and pipes:

1. A pipe is a vessel – a tube is structural

2. A pipe is measured ID – a tube is measured ODA hollow cylinder has 3 important dimensions which are: The outside diameter (OD)The inside diameter (ID)The wall thickness (WT) These three are related by a very simple equation: OD = ID + 2 * WT

3. One can completely specify a piece of pipe/tube by supplying any two of these numbers

From the Jan/Feb issue of Branch 68 NZART “Ragchew” Newsletter

Baluns may be would in all sorts of configurations to change impedances and change input/output line feeds. One of the two most popular baluns are the 50 Ohm Un-balanced to 200 Ohms balanced configurations. The other is the 50 Ohms un-balanced to 50 ohms balanced configuration. The first balun 50 Ohms to 200 ohms are often used to feed Of Centre Fed dipoles and G5RV and antennas while the second balun 50 ohms to 50 ohms simply provides a match and keeps RF off the feedline. Both configurations require the same initial toroid and windings to cover to HF bands from 3 t0 30 Mhz with little actual loss.

The photo shows how the windings are wound on the toroid which must be robust enough to handle 1KW and be wound with fibreglass tape to prevent the copper windings digging in on the edges of the toroid and shorting a few windings or arcing into the ferrite toroid under higher power transfer.

The finished toroid Balun ready to to be sealed in it’s plastic box and connected into the dipole antenna. This particular version used 16 Turns of #14 wire evenly spaced around the T-43 ferrite core. The core was 55mm in diameter and 20mm thick. Amidon in the USA and many other suppliers around the world sell them.

The finished balun should be put into a suitable plastic box sealed from weather and rain with suitable connections to each leg of the dipole and and with an SO-239 socket for the coaxial feedline.

Baluns are not difficult to wind and are very much less expensive than buying a commercially made unit.

73, Lee ZL2AL

I’ve rebuilt a lot of HyGain and Mosely antennas over the years and recently built a copy of a Force 12 Tribander from assorted scrounged corroded tubing. Aluminium corrodes over time and it’s a problem. There are a few things that you can do to take the work out of corroded tubing.

1) Most hardware stores and some engineering supply companies have a 3M product which fits into an electric drill chuck. The abrasive wheel part is a course raspy hard synthetic wheel designed to remove paint. It comes with it’s own arbour shaft and the abrasive wheel is about 120mm diameter and about 30mm thick. It takes all the work out of restoring the outside of any badly corroded alloy tube. One wheel will last long enough to restore the shine to most 3 or 4 el.

2) The second problem is cleaning the inside end of tubing. You just can’t get at it easily and you need to so that good quality contact is made with the next tube that slips inside. I solved the problem by going into a gun shop and buying 2 brass wire brush rifle pull throughs normally used to clean barrels. They are about 90mm in length with brass bristles and have a 1/4″ shaft. The small one will clean the inside of 3/8″ up to about 5/8″ tubing. The larger one for a 12 gauge shotgun does the larger tubes. To use them, I soldered on a 6″ long, 1/4 dia shaft extension onto the pullthrough shaft and put the shaft in a cordless drill running at slow speed. it works a treat and the tubing insides are sparkling clean!

3) For the past 20 years i have used a electricians conduction compound made by Utillux It’s P/N is H-2397 Jointing Compound. It preserves and conducts between the metal tubes. Brilliant.

4) I don’t rely on clamps any more. Although I use them and tighten them, I also use 1/8 Pop rivets in the same way that Force-12 do to secure the elements in their antennas.

5) Have a look at /3219/

73, Lee ZL2AL

There are a lot of “orphan” Icom power supplies that you see at the ham car boot sales and flea markets. They usually go very cheaply because they were originally purchased with the Icom 701 and the Icom 720. Both these models of radios have had problems over the years and their owners have moved on. Even though the radios are gone, the power supplies are heavy duty and built to last which is why there are plenty of them still out there. There are two models. The IC PS-701 was the original and it had a large transformer and very good filtering. When the IC720 was marketed, Icom sold the matching PS20 power supply and it is a newer, switch mode design. Even though many cheap switchmode supplies have a bad reputation, the Icom design was very well engineered with the switchmode components in a rugged diecast alloy box with a heat sink on the back. No RFI noise at all with the advantage of plenty of overload protection and excellent voltage regulation. The PS 701 is not really suited as it’s output voltage is 17 VDC unloaded and measures about 15 VDC fully loaded. It could be used if an on board regulator was installed. I have not looked at the internal circuitry of the IC-701 but suspect that the radio has in internal regulator. For our purposes I will only concentrate on the PS20.

I picked up a model PS-20 cheaply a while ago and thought that it would make an excellent power supply for any of today’s modern radios as the design is rated 13.8 volts at 20 amps. The cabinet is well constructed and it has a good quality speaker behind the front panel.

Conversion to a universal supply requires removing the very large DC cable from the back, moving the ground post, installing a pair of terminal posts and putting a switch on the front panel.

The original design has one small slide switch on the back panel to sever the line voltage input. The only way of turning on the supply, other that connecting to the Icom radio is the ground the orange wire in the main DC cable via a second switch on the front or rear panel to activate the relay that puts line voltage to the unit. After removing the top and bottom covers the conversion as follows:

1) Cut the rear cable about 6 inches out from the back panel and peel back the outside plastic sheath. This exposes a red and black wires which is the DC output. It also exposes the orange control wire.

2) Remove the ground post and place it next to the AC input connector.

3) Make up a small alloy or steel plate as shown in the photograph with two terminal posts on the plate and mount it where the old cable hole is. You may have to do a pit of filing and trimming to make it all fit. I used 4 x 3mm screws to hold the plate in place.

4) Connect the red and black wires to the two posts.

5) Mount a main Off/On switch on the front panel. I used a small rocker switch and fitted it into the plastic front escutcheon to the left of the LED an the right hand side of the panel.

6) Connect the Orange wire to the switch and the other terminal to ground on the chassis somewhere.

7) Finished and ready to turn on!

It is a simple and easy conversion to a quality power supply for a very reasonable price. Photos are attached

73, Lee ZL2AL

Here are the main points.

1) If it IS the TV, SOMETHING connected to it is acting as a 160

meter transmitting antenna and radiating it strongly enough for your

receiving antennas to pick it up.

2) There may be more than two antennas. Prime candidates are whatever

that TV is using as a signal source (cable TV, satellite, roof

antenna), the power line, and even connections to the audio system.

3) Like any other 160 antenna, bigger makes a better transmitter, so

use your noggin in figuring out which of these antennas are most

likely to be the most effective long wire antennas.

4) Apply BIG ferrite chokes to those antennas (not your antennas, the

ones connected to the TV). What you are looking for is the greatest

possible impedance from the choke on the frequencies where you are

hearing trash. See the tutorial on my website to learn how to get

that high impedance. It includes graphs of lots of MEASURED data

contributed by another member of this list who did them in a very

good lab.

http://audiosystemsgroup.com/SAC0305Ferrites.pdf

While the tutorial is written for pro audio people, any decent RF guy

should be able to use it to understand, troubleshoot, and fix ham RFI

problems. I’m working on a tutorial dedicated to ham radio

applications.

5) You need Z on the order of several K Ohms to make a serious dent

in this trash. As the data shows, for 160, you are wasting your time

(and money) with anything less than 10-14 turns around a 2.4″ #31

toroid, or 7-8 turns through one of the biggest #31 clamp-ons.

6) Do NOT try to kill the noise by finding “a better earth

connection” for that system. Any noise that you shove into that

ground wire will radiate, just like any other antenna carrying RF

current.

7) If you are going to put a commercial AC line filter on the set,

make sure that you have the shortest possible connection between the

filter and the set, ESPECIALLY for the green wire. See #6 above.

8) 12-14 turns of twisted pair like THHN stranded around that #31

2.4″ toroid makes a very good common mode choke for 160-40 meters.

Run only “hot” and neutral through the toroid, carry the green wire

around it. Put an RF cap of at least 0.33 uF between line and neutral

on the power source side of the choke. This cap will form a

differential mode filter with the imbalance in the inductance of the

choke. It must be rated for the AC line voltage. The wire in this

choke doesn’t need to be very big — the vast majority of standard

IEC power cords are #18, even those that look a lot beefier.

9) Do NOT add capacitance between hot or neutral and the green wire.

In addition to #6 above, doing so would create more leakage current

at power frequencies than is permitted under safety codes.

73, Jim Brown K9YC

Decibels Made Easy (Without Logarithms)by Bruce Spratling, Jr.

Suppose your station has a transmitter that puts out 50 watts of power, a feed line that loses all but 40% of the power, a duplexer that loses half the power, and an antenna that produces enough gain to make the signal 4 times as strong as a dipole antenna. To find the effective radiated power of your station you need to multiply 50 watts times .4 (feed line loss) times .5 (duplexer loss) times 4 (antenna gain) = 40 watts.

Rather than multiply all these factors together, someone decided it would be good to represent them in a way that allows us to add them. An increase of a factor of 10 is defined to be a 10 decibel increase. Decibels are abbreviated dB. Two 10dB increases produces a 20dB increase, because we add decibel increases.

Two increases by a factor of 10 results in an increase of 10 X 10 = 100; therefore 20dB = 100. Three 10dB increases is 30dB, which is 10 X 10 X 10 = 1000.

Because we want to be able to add the dB increases, 0 dB is a factor of 1. Multiplying something by 1 does not change it, just as adding 0 to something results in no change.

Decibels 0 10 20 30

Factor 1 10 100 1000

It’s easy to figure out the meaning of 10, 20, 30, 40… dB, but how about decibels less than 10? Note that if we multiply 2 by itself 10 times, it generates the following: 2, 4, 8, 16, 32, 64, 128, 256, 512, 1024.

2 times itself 10 times is 1024, which is slightly more than 1000, which is 30dB. 3 added to itself 10 times is 30, and 30dB is a factor of 1000. Therefore, 3dB represents a factor of (approximately) 2.

Another way to derive that 3dB represents a factor of 2 is this: If we add 3dB to itself 3 times we get 9dB, which is less than, but close to, 10dB. If we multiply 2 times itself 3 times we get 2X2X2=8, which is close to, but less than 10. This is good because 9dB should be less than 10 (since 10 dB is 10). We have to multiply 8 by 5/4 to equal 10, and we have to add 1dB to 9dB to equal 10dB. Having 3dB = 2 will work if 1dB = 5/4.

Does 1 dB represent a factor of 5/4? If we apply 1dB 3 times, we’ll have 3dB, which = 2. (5/4)X(5/4)X(5/4) = 125/64, which is close to 2. Therefore, a 3dB increase represents a 2 times increase, and 1 dB represents an increase of 1.25.

6dB = 3dB + 3dB. A 3dB increase is a factor of 2, so 6dB = 2 X 2 = 4. Similarly, 9 dB = 2 X 2 X 2 = 8.

So far we have:

Decibels 0 1 2 3 4 5 6 7 8 9 10

Factor 1 1.25 2 4 8 10

Let’s consider negative decibels. -1dB changes 10dB to 9dB, which changes 10 to 8. Therefore, -1 dB is .8, because .8 times 10 = 8.

To find 8dB, think of 8dB as 9dB – 1dB = 8 X .8 = 6.4. To find 5dB, think of 5dB as 6dB – 1dB = 4 times .8 = 3.2. Note that 5dB + 5dB = 10dB = 10. Using 5dB = 3.2: 3.2 X 3.2 = 10.24, which is about 10. To find 2dB, use 2dB = 3dB – 1dB = 2 X .8 = 1.6

Decibels 0 1 2 3 4 5 6 7 8 9 10

Estimated Factor 1 1.25 1.6 2 2.5 3.2 4 5 6.4 8 10

Actual Value 1 1.26 1.58 1.99 2.51 3.16 3.985 5.01 6.31 7.94 10

% Error .714 -.944 -.236 .475 .178 -.473 .237 -1.41 -.708 0

You’ll notice from the chart that the results are all within 1.5%.

To summarize the system:

Realize that 3dB = 2, so 6dB = 4, and 9dB = 8.

You know the value for 3, 6, and 9dB (2, 4, 8).

To find 2, 5, or 8dB (1 less than 3dB, 6dB, or 9dB), use -1dB = .8.

If you want to know 4 or 7dB (1 more than 3dB or 6dB), use 1dB = 1.25.

To find fractions of 1dB, realize that 1dB represents a 25% increase, so .1dB is a 2.5% increase, .2dB is a 5% increase, .4dB is a 10% increase. (This interpolation method isn’t exact, but it’s fairly close when dealing with such small values).

You can carry this further for hundredths of a decibel. .01dB is one tenth of .1dB. .1dB is 2.5%, so .01dB is .25%. .04 dB is 1%.

An example: Suppose an antenna has a gain of 17.68 dB. How much increase is this? Note that 17.68 = 10 + 7 + .68. A 10 dB increase is a factor of 10. A 7 dB increase is a factor of 5. Therefore, a 17 dB increase is a factor of 10 X 5 = 50. .6 dB is 15%, .08 dB is 2%, so .68 dB is about 17%. 50 X 1.17 = 58.5, so the antenna increases the signal strength by a factor of 58.5, the signal is 58.5 times as strong (the exact value is 58.61).

Another example: An antenna’s signal is 25 times stronger than a dipole antenna. How many decibels is this?

This is actually quite easy. A 10 dB increase is a factor of 10. Because 25 = 10 X 2.5, we still have an increase of 2.5 to account for. An increase of 2.5 is 4 dB, so the total increase = 10 dB + 4 dB = 14 dB (the exact value is 13.98 dB).

Suppose we have an increase of a factor of 30. How many decibels is this? 30 = 10 X 3. To multiply by 10 requires 10dB. But, we need to add the decibels needed to multiply by 3. 4dB is 2.5, but we need 20% more (3 is 20% more than 2.5). 20% is about .8dB, so 30 = 14.8dB (the exact value is 14.77).

Well, that’s my system for decibels, and as promised, I didn’t mention logarithms!

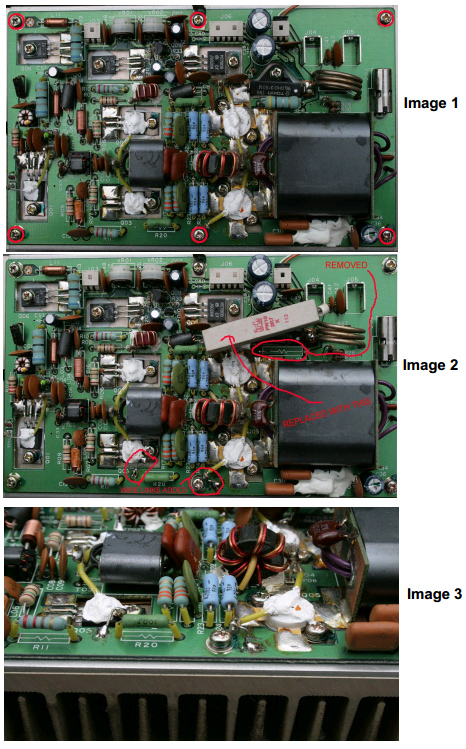

Inspection of the PA unit revealed that in addition to the driver transistors Q7002 & Q7003 being short circuit, R7014 had disintegrated and that L11 had overheated. The finals were undamaged. I knew that this particular radio had had a long history of abuse which resulted in at least two driver transistor pair replacements in the past.

After fitting yet another matched pair of MRF486’s, I decided to replace anything else which might have caused the previous failures. I was mystified as to why L11 had been overheating and concluded that replacing the 8 volt bias supply regulator which is common to the pre-driver stage as well as the driver and final stages would be prudent. After some thought I decided that I would also replace both the biasing transistors and both pots (Q7006, Q7007, VR7001 & VR7002). All other components around these stages measured OK. R7014 was originally 0.4 ohm 2 watt mounted on the PC board, but a service memo shows it’s value as 2.7 ohm 10 watt mounted above the PC board.

Eventually with all new components installed and new thermal compound under the transistors, we were ready to switch on. The finals idle current was adjusted without trouble but the driver current was extremely high and would not adjust at all. After rechecking everything again and soldering on an odd pair of diodes in place of D7003 & D7004 everything worked. I mounted the replacement diodes in place of the originals and switched on again. (Image 1 & 2)

Mounting these correctly resulted in the original overcurrent symptom recurring. It turned out that the solder lug which holds down Q7006 was intermittent! Although it was firmly tightened down, gentle flexing caused the earth bond to come and go.

I soldered a short length of wire from this lug to the PC board earth plane and did the same to the diodes in the final stage as well. Switch on, press the MOX button and NO SMOKE! The idle current was adjusted to give 260 millivolts across R7014 (100 Ma) and now the rig worked just the way it should. (Image 3).

The driver idle current is measured by noting the voltage drop across R7014. If this is a 0.4 ohm, you should have a 40 millivolt drop. If it is a 2.7 ohm, you should have 270 millivolts. The final idle current is adjusted in the same way, measuring the drop of 6 millivolts across R7027 (0.025 ohm) while adjusting VR7002.

After this exercise I took a look at my own FT1000 PA unit so as to modify it before it was too late. I discovered that all the all the PC board mounting screws were loose. If the screw holding the diode network in the final stage were to fail, goodbye finals! I suspect that there are many more rigs out there with the same potential problem. While the covers were off, I checked the tightness of all the other PC board mounting screws.

If you have the ability and knowledge to carry out this modification and screw check – do it before it is too late. The rig has been tested on air for some time and has shown no sign of failure. As R7014 is higher in value than the original, it produces slightly more heat than the original 0.4 ohm resistor. This is normal.

The pictures show which screws need checking and where to fit the earth links. Do not attempt this procedure if you are not fully competent and do not have the necessary skills and tools.

Peter ZL2LF

[email protected]

RF getting loose in your shack is a common problem. Especially with high power, multi antennas and cables into the shack and cunning USB devices that do not have a lot of protection from the myriad of wires shielded and unshielded that weave around the back of the operating desk. I operate two setups on the desk and two amplifiers. You can see the setup on QRZ.com and as it only prevalent on 80/40 (trap dipole) and 30M (full size loop) I decided to stop living with the problem and do something about it.

The symptoms included, drop out of USB device from radio to computer (only on one radio/amp at some times) I also had keyboard lockup and experienced a fair sized buzz from one of the two speakers in time with any CW sent out from the Quadra amp. The Tokyo HP amp didn’t do it. My rotator control box would suddenly move the needle and the compass lights would flash with CW. The whole experience with a KW up the spout was quite exciting. It was also damned annoying!

The first thing most hams do is to buy a bunch of ferrite cores and snap on devices and load up the cables one by one. I did that and quickly ran out of ferrite devices and money with minimal improvement. Not much, but some. The most noticeable improvement came when I put ferrite on the rotator cable from outside as it was picking up RF from the LF antennas and bringing it into the shack.

I then decided to ground the whole station. RF grounding is something I never had had to do in 60 years of ham radio. Usually, the shields of coax cable tied everything together and that was grounded back to the mains power supply. Obviously it wasn’t working for me. A bit of research on the net pointed out that grounding doesn’t work if you “chain” one piece of equipment to another which is what coax cables do.

I went to the local electrical wholesaler and bought a brass bussbar with 12 slots and a small roll of #12 stranded wire and proceeded to wire each individual unit to the common bussbar. I also ran ground leads from the AC input filter to the station and from all the antenna switches. Oh yes, also the computer, and the speaker cabinet.

The result wa that it all worked as it should. No problems with any combination of radios, amps or antennas. The only problem that remained was the keyboard which still continued to lock up! I replaced it with another and it did the same thing. A few weeks later I mentioned the problem to another ham also involved with I.T He asked if the keyboard was a good quality one with a metal chassis or a cheap one that’s all plastic and suggested a HP keyboard as they have a metal chassis and a great quality build. I bought one and have never experience keyboard lockup since. I bought several more for our contest group ZM4T as they just feel good to use. The USB to Serial cable into the Maxtor CT17 for the Icom works fine now without any protection.

That’s was my experience. I solved the original problem and have since have removed over half the ferrite snap-ons. Maybe some of these ideas will help you with your RF problems.

73, Lee ZL2AL

Will we ever be able to dispel the myths?

This is a much beaten-up subject. Hardly a day goes by that on some ham radio board or reflector there isn’t a question about “station grounding.” Funny part is, the subject’s been so discussed, that anyone asking a question must have not been paying attention for the past several (fill in: days, weeks, months, years).

Problem

I think the biggest problem is that a lot of commercially manufactured equipment comes complete with a “ground terminal,” usually somewhere on the rear of its chassis. That, along with directions from the equipment manufacturers, implies the equipment owner ought to connect something to it.

I view this as an adjunct to the “SWR” dilemma. You know, the one that drives hams crazy believing that for an antenna to work properly it must have a low SWR. Or, sillier still, that an antenna with a low SWR must be working properly.

It’s funny that before about 1960, few hams owned an SWR measuring instrument of any sort but somehow made DXCC, bounced signals off the moon, worked meteor scatter, aurora and E-skip, and just happily made contacts without having the foggiest idea what their antenna’s SWR was. Commercial transmitters didn’t have internal SWR bridges, and inexpensive bridges weren’t on the market. The famous “Monimatch” circuit hadn’t yet been published, so few hams knew how to build an SWR bridge, nor would they bother trying. Hams, and their transmitters, were perfectly content to be working each other, around the world, without this fabulous knowledge.

Now, back then it was also pretty common for a lot of equipment to not even have a ground terminal. Some of it did, some of it didn’t, and it didn’t matter much one way or the other. I think the best reason for a ground terminal would have been to help prevent equipment users from killing themselves due to internal short-circuits in equipment that was AC powered, back before 3-prong (and 3-wire) power cords, plugs and outlets became common.

Ironically, the most unsafe equipment back in those days was thousands – if not millions – of inexpensive, AC-line powered broadcast radios, including bedside “All American Five” type radios and clock radios, which did not use AC line isolation transformers. To minimize production cost, a lot of these radios directly rectified the AC line and fed a full 120 volts AC to a series string of tube filaments. The string totalled around 120 volts, so no filament transformer was needed. One side of the AC mains was connected directly to the radio chassis (preferably, the “cold” side of the mains!), and to prevent people from touching the chassis, the little radios were installed in plastic enclosures and used plastic knobs over the control shafts. These radios did not have 3-wire power cords.

Those were accidents waiting to happen, of course. Untold thousands of people received electrical shocks from these radios, and they were responsible for more than a few fires. Sadly, some probably lost their lives due to such shabby design.

And while those radios really indicated an actual need for a chassis (earth, safety) ground, they didn’t have any provision for one.

But we don’t use radios like that any more. Now, we have equipment that uses isolation transformers, and 3-wire power cords plugged into grounded outlets. And a lot of our equipment is powered by low voltage DC, where a shock hazard is literally nonexistent. (You can be hurt by low voltage DC, but not electrocuted. The major source of injuries to people working with low voltage DC is in the form of burns caused by jewelry shorting out the DC power supply’s output bus, which can often pump dozens of Amperes through a ring or bracelet before shutting down – if it ever shuts down.)

So, why do we ground?

Really good question. I guess I’d preface my answer with this simple statement:

I’ve been a licensed ham for 39 years, and continually active. I run legal-limit amplifiers and power output on 160 meters through 10 meters, a kilowatt on 6 and 2 meters, and a couple hundred watts on 135cm and 70cm, and sometimes on 33cm and 23cm, too. I’ve used dozens of different antenna configurations and have operated from all over the world, but mostly from any of the fifteen home-station hamshacks I’ve built over the years at the various homes I’ve owned.

And in all that time, I’ve never once had a “station ground” of any sort.

And in all that time, I’ve never had any problem that grounding would solve.

I’ve operated mobile, marine mobile, maritime mobile and aeronautical mobile and never had a ground on any of these vehicles, either. Especially when operating from an aircraft, that’s hard to do. I’ve also set up dozens of field operations, including Field Day and other contests, without ever owning a ground rod or feeling the need to drive one in, anywhere.

Therefore, you can see I’d be a tough one to convince that a “station ground” serves any particular purpose. Not to say it cannot help, in some situations. But in most all those situations, better station engineering would help more.

(For clarification: Nowhere in this article will I say it’s a bad thing to ground your equipment. I just discuss the counterpoint, that grounding your equipment usually isn’t necessary, and if you’re spending any time deliberating on this issue, that’s time wasted that you could be operating, instead.)

RF Grounding

There’s surely such a thing, and it’s a good thing. If I ever use a voltage-fed antenna or a random wire, I usually place my antenna tuner outdoors, or at least in an open window, so the entire antenna is literally outside, and then I have a very short and direct path to Mother Earth for the return current. The earth completes the current path from transmitter to antenna and back, and everything is happy. This is a great situation. But you really need to have the tuner laying on the ground, or very darned close to it, to accomplish this feat – because a tuner sitting on a desk in the shack is often too far from ground to be effectively grounded.

Usually, however, I use current-fed antennas and I match the antennas to their transmission lines (by adjusting the antennas themselves). Most of my lines are coaxial cable, but some are twin lead. If I use coax to feed a balanced antenna, I use a current balun at the antenna feedpoint. If I use twin lead to feed a balanced antenna, I don’t need a balun, except perhaps in the shack where I transition to 50 Ohm equipment. In all cases, the lines are cool and quiet and don’t seem to bring any RF back “down the pipe” from antenna into the shack.

That’s the result of matching, choking and cable routing to minimize this problem. That not only works better than grounding the station equipment, but it’s also easier to accomplish, usually.

It’s true that most antenna designs won’t provide a good match over more than maybe 2% of the operating frequency. So what? My 80 meter inverted vee is resonant at 3.750 MHz, and its SWR rises to >3:1 at both band edges (upper and lower). Yep, that’s about 25% reflected power. Okay, I’ll repeat: So what? I use my amplifiers as antenna tuners, can transfer all the power generated to the load just fine, and have zero RFI, RF “feedback,” or other problems. No “hot mikes,” no burns from accessories, no nothing, nada, zip. The secret is station engineering. That is, my antennas are located sufficiently far from my equipment that very little radiates back into places I don’t want it to be. And, I do use current baluns in the form of coaxial RF chokes and the like; and, for stubborn cases (especially on the very lower frequency bands, where it’s difficult to escape the antenna’s near field) I use ferrite isolators on the feedlines, installed just outside the shack wall.

I obviously don’t need any station “RF ground,” and never made any attempt to have one.

Lightning

I live inLos Angeles, which has the lowest incidence of lightning strikes of anywhere in theU.S.(fewer than 5 lightning incidents annually on average, and that’s recorded in the mountains or high desert, not where I live). But, it doesn’t matter. I grew up inNew Jersey(70+/year) and have lived inFlorida(90+ but it seems like a million), and have operated from many tropical places where lightning is so common that people miss it if it doesn’t happen daily.

Fact is, grounding your equipment chassis inside your home doesn’t do anything to prevent lightning damage, anyway. The last place you want lightning energy to find a path to earth is inside your home. The only place you want lightning energy to find a path to earth is outside your home. Volumes have been written on this subject by people more knowledgeable than I, so I’d refer you to those volumes for more information.

The only thing I’ll say is, “Equipment (chassis) grounding is not helpful with regard to lightning protection.” And that fact ought to be self-evident to anyone who understands electricity.

Safety ground?

As I mentioned earlier, there are very valid reasons for “safety” grounding, although I’ve never once had an equipment fault that would have caused a safety concern whether the equipment was grounded, or not. But, it’s possible. And, it’s the reason that all construction in the past 30+ years inAmerica(and many other places) used 3-wire grounded outlets throughout. The third (green, ground) wire should be connected to the ground buss in the building’s electrical service panel, which should be grounded directly to earth via an 8′ ground rod driven into earth at the nearest practical location, usually directly under the panel.

It’s possible that even this excellent protocol can fail, but it’s rare. In the event it does fail, a secondary earth ground for station equipment is a “belt and suspenders” approach that probably can’t hurt. I must say, though, that having owned hundreds of pieces of AC-powered electronic equipment in my nearly 40 year ham career, I’ve never seen a fault occur that would cause an electrical shock during normal operation. So, I do believe this is a pretty rare event.

[I might also say that I’ve received numerous electrical shocks over the years, all of which were purely my fault (like replacing wall outlets and switches without bothering to turn them off first), so I deserved every one of them. And they didn’t feel so bad. I can say from experience: 240v hurts much more than 120v. If you’re going to shock yourself, go for 120. It’s much nicer. In Japan, their mains voltage is only about 100 volts. Now I know why: It hurts even less.]

Daisy chain grounding

This is not recommended at all, but we all have it, in one way or another. Unless your station is set up an inch from your service panel, where a SPG (single point ground) connects every single thing going to and from your home and the impedance between all those items is zero: You, too, have some form of a daisy-chain ground.

This is nothing more than having equipment grounded via multiple paths, both serial and parallel, that have varying impedances to earth. It’s difficult to avoid.

For example: If your antennas are mounted on your tower, and your tower’s grounded, your antennas, unless completely isolated from their supporting structure, are grounded, too. Now, you use coaxial cable to connect those antennas to your station tuner, coax switches, amplifiers, rigs, or whatever, and you have a ground path from your antennas far, far away to your station equipment right in front of you, via all the coaxial shields. The DC resistance of all those shields is an unknown, although you could probably calculate or even measure it, if you try. But, if you have four antennas fed with four runs of 100 feet each RG-213/U, you’ve got four parallel ground paths that probably have a DC resistance less than one Ohm.

So, even if you disconnect every intentional earth ground you have in your station, your station equipment is still grounded, anyway. It’s just a rather unpredictable ground. If you don’t have a tower, but use a mast on the chimney to support your antenna, that mast should be grounded by a wire of substantial diameter directly to a ground rod via the shortest possible path. If you use a doublet antenna that is fully isolated from ground, then its feedline should be grounded via a lightning arrestor or similar device prior to entering your shack.

No matter how you cut it, your stuff is grounded (if you have an engineered installation), like it or not. So, the “safety ground” consideration, to prevent electrical shock in the event of internal equipment malfunction, is very likely covered. A 1 Ohm connection to earth will keep a 120v line down to 15v before it trips the 15A circuit breaker or fuse in a conventional household circuit. You won’t feel the 15 volts.

If your home is equipped with 3-wire grounded outlets and your power supplies or other equipment containing AC-powered circuits have 3-wire power cords, now you have another ground, in parallel with that one.

If you added still another chassis ground simply because you wanted to, now you have still another ground, in parallel with the other two. But the circuit is more complex than just parallel branches to earth, and from an AC (RF) perspective it’s more complex still.

As far as I’m concerned, the only important consideration in all of this is that the transmission line from my antennas to my station equipment should have considerably higher ground impedance than the outdoor ground connection from those same antennas to earth. So, when in doubt about that, I use more coax than needed for the path. This is purely a lightning protection issue, and I live where lightning hasn’t been witnessed in sixteen years; but I try to follow that rule, anyway.

Still want to connect something to that little terminal?

Go ahead, if you want to. But think about why. “Because the terminal is there” isn’t a very good reason. The little pictograms in the ham radio equipment owners’ manuals (especially the JA stuff) isn’t a very good reason, either. My Kenwood owner’s manual has the little grounding pictorial, along with a warning to be sure the equipment is grounded, with no explanation at all as to “why.” Interestingly, I have lots of Kenwood audio equipment that doesn’t even have a 3-wire power cord, and there’s no ground terminal on any of it. Same company, different philosophy.

Maybe Kenwood believes that because amateur transceivers are capable of transmitting, they — unlike receivers — need a ground?

Even more interesting is the fact that the stereo equipment really could benefit from an earth ground. In one case of RFI I had personally, adding a ferrite choke filter to the AC power cord, and a chassis ground to a “surround sound” stereo receiver, completely eliminated the interference.

Let the flames begin

The “must ground” crowd – and there is one, somewhere – will likely disagree with all of this. That’s fine. Remember, this whole piece is not about lightning protection in any way; it’s about interior station equipment grounding. Since I’ve never used any in 39 years, I probably never will. I’m not suggesting that equipment grounding is wrong, just that it’s usually unnecessary – and if you find it to be necessary, you’ve got other problems that can be fixed in other ways.

Steve Katz, WB2WIK/6